Product

Polyimide Tape

Premium polyimide tape (Kapton®) - withstands extreme temps (-269°C to +400°C), UL94 V-0 flame retardant. Ideal for PCB soldering, EV batteries & aerospace.

Polyimide Tape–High-Temperature Resistant Kapton® Tape for Electronics & Industrial Use

Product Overview

Polyimide Tape (also known as Kapton® Tape) is a premium high-temperature resistant tape made from polyimide film with silicone adhesive. Designed for extreme heat, chemical resistance, and electrical insulation, it is widely used in electronics manufacturing, aerospace, automotive, and PCB repair.

1.Ultra-High Temp Resistance (-269°C to +400°C)

2.Flame Retardant – UL94 V-0 Certified

3.No Residue Removal – Clean release after heat exposure

4.Excellent Dielectric Strength (>10 kV/mm)

5.Chemical & UV Resistant – Withstands acids, solvents, and radiation

Technical Specifications

| Property | Specification |

|---|---|

| Material | Polyimide Film + Silicone Adhesive |

| Thickness | 0.025mm – 0.05mm (1mil – 2mil) |

| Width Options | 3mm – 50mm (Custom Sizes Available) |

| Temperature Range | -269°C to +400°C (-452°F to +752°F) |

| Adhesion Strength | ≥ 5 N/25mm |

| Dielectric Strength | >10 kV/mm |

| Tensile Strength | 200 MPa |

| Flame Rating | UL94 V-0 |

| Certifications | RoHS, Halogen-Free |

Key Benefits

1. Extreme Heat Resistance

•Withstands soldering (260°C+), powder coating, and thermal cycling

•Ideal for PCB masking during reflow/wave soldering

2. Superior Electrical Insulation

•Prevents short circuits in high-voltage applications

•Used in battery insulation (Li-ion, EV power packs)

3. Chemical & Environmental Durability

•Resists acids, solvents, oils, and UV radiation

•No degradation in harsh industrial environments

4. Clean & Residue-Free

•Silicone adhesive leaves no sticky residue

•Easy removal after high-heat processes

Applications

1.Electronics & PCB Manufacturing

•SMT masking during soldering

•Flexible circuit (FPC) protection

•BGA & QFP component rework

2.Automotive & Aerospace

•EV battery insulation

•Wire harness heat shielding

•Engine compartment high-temp protection

3.Industrial & DIY

•3D printer heat bed adhesion

•Powder coating masking

•High-temperature gasketing

FAQ (Frequently Asked Questions)

Q: How does polyimide tape compare to regular electrical tape?

A: Polyimide tape offers far higher temperature resistance (up to 400°C vs 80°C for PVC tape) and better chemical/electrical performance.

Q: Can it be used for lithium battery insulation?

A: Yes! It's ideal for Li-ion battery cell wrapping due to its heat resistance and flame retardancy.

Q: Does the adhesive melt under high heat?

A: No! The silicone adhesive remains stable even at 260°C+ (500°F).

Q: Is it reusable?

A: No, it's designed for single-use high-temp applications.

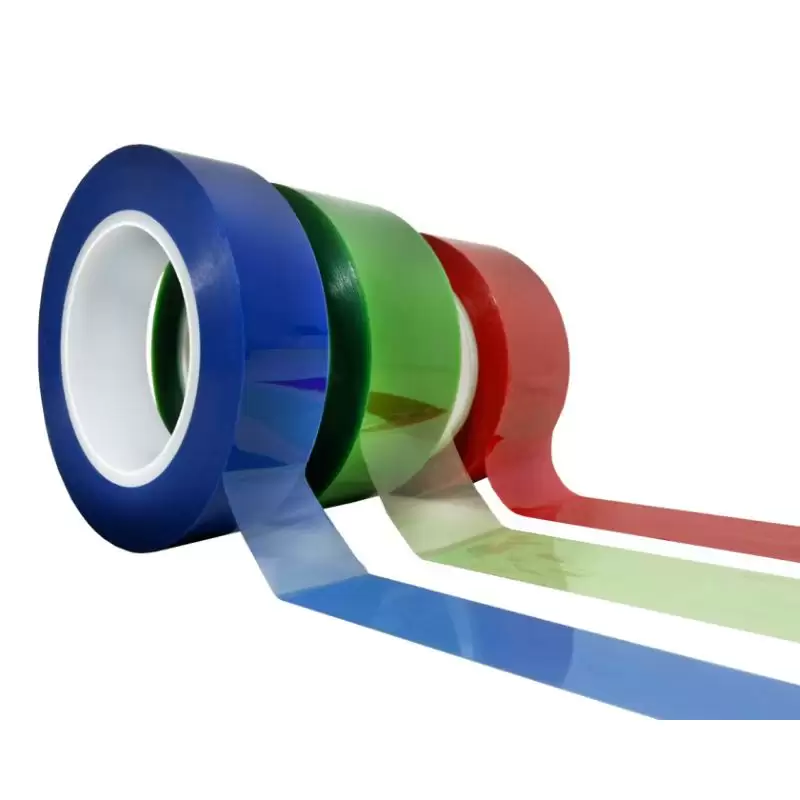

Q: What colors are available?

A: Standard amber (gold), also black (matte/gloss), and red for color-coding.

Q: Can it be laser-cut for custom shapes?

A: Yes! Polyimide film is precision-cuttable for specialized applications.

Why Choose Our Polyimide Tape?

1.OEM Quality–Used by top electronics manufacturers

2.Wider Temp Range Than Competitors (-269°C to +400°C)

3.Clean Removal–No messy residue after heat exposure

4.Multiple Sizes–From 3mm narrow tape to 50mm wide rolls

Perfect For:

PCB assembly technicians

EV battery engineers

Aerospace & automotive suppliers

Industrial equipment manufacturers