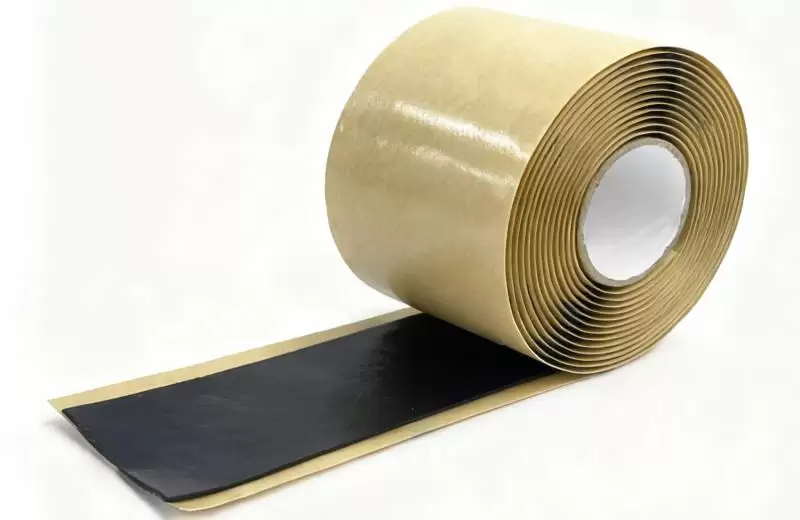

Butyl tape seems like a miracle product - until you encounter that one surface where it simply won't adhere. Understanding what butyl tape rubber materials don't bond with can save you from failed projects and frustrating cleanups. Through 15+ years at QKD, we've identified the surfaces that challenge even the best butyl waterproof tape.

The Science Behind Butyl Adhesion

To understand why butyl tape fails on certain surfaces, we need to examine how it creates bonds. Butyl sealing tape relies on slow flow and surface wetting to form permanent seals. The tape gradually conforms to microscopic surface imperfections, creating mechanical and chemical bonds.

However, three factors typically prevent proper adhesion:

1.Low surface energy material

2.Contaminated or unstable surfaces

3.Chemical incompatibility

Problem Surfaces: Where Butyl Tape Fails

Polyethylene and Polypropylene Plastics

These common plastics present the biggest challenge for butyl tape black and other variants. Their chemically inert, non-porous surfaces have extremely low surface energy, meaning the adhesive can't establish a proper bond. You'll find these materials in:

• Plastic storage containers

• Some outdoor furniture

• Certain water pipes

• Plastic planters and garden equipment

Silicone-Coated or Treated Surfaces

Silicone creates a barrier that butyl waterproof tape cannot penetrate. This includes:

• Previously siliconed areas

• Silicone-based paint additives

• Baking sheets and cookware

• Waterproof clothing and gear

Dusty or Powdery Surfaces

Any surface with loose particles prevents direct contact. The butyl tape rubber will stick to the dust rather than the surface beneath. Common examples:

• Unprimed drywall

• Chalking paint

• Weathered wood

• Concrete with surface dust

Oily or Greasy Metals

While butyl typically bonds well with clean metals, any petroleum-based contamination causes failure:

• Uncleaned automotive panels

• Kitchen range hoods

• Machinery with oil residue

• Garage floors with oil stains

Wet or Frozen Surfaces

Water prevents the direct contact needed for butyl sealing tape to adhere properly:

• Rain-wet windows

• Condensing pipes

• Icy surfaces

• High-humidity environments

Special Considerations for Double Sided Butyl Tape

Double sided butyl tape faces additional challenges because both surfaces must be compatible. The tape's effectiveness depends on perfect conditions on both sides, making surface preparation even more critical.

Surface Preparation: Making Problem Surfaces Work

Sometimes you need butyl tape to work on less-than-ideal surfaces. Here's how to improve adhesion:

1.For Plastics

• Lightly sand with 120-grit sandpaper

• Clean with isopropyl alcohol

• Apply plastic primer designed for adhesion promotion

• Use specialized butyl tape black formulated for low-surface-energy materials

2.For Oily Metals

• Degrease with automotive wax and grease remover

• Wipe with lacquer thinner (test first)

• Scuff with red scotch-brite pad

• Apply immediately after cleaning

3.For Dusty Surfaces

• Brush or vacuum thoroughly

• Wipe with tack cloth

• Apply primer to lock in remaining particles

• Use heavier butyl tape rubber that can compress through minor contamination

4.Testing Surface Compatibility

Always test butyl tape on an inconspicuous area first. Apply a small piece of butyl waterproof tape, press firmly, and wait 24 hours. Attempt to peel it back - proper adhesion should require significant force and leave adhesive residue on both surfaces.

The QKD Approach to Challenging Surfaces

Through 15+ years of manufacturing experience, QKD has developed butyl tapes that handle difficult surfaces better than standard products. Our butyl sealing tape formulations include:

• Enhanced surface wetting agents

• Higher initial tack for problematic materials

• Better contamination tolerance

• Temperature-resistant adhesion

When to Consider Alternative Solutions

Some surfaces simply won't work with butyl tape, no matter how you prepare them. Consider these alternatives:

1.For Polyethylene/Polypropylene

Specialty plastic adhesives

Mechanical fasteners

Surface activation through flame treatment

2.For Silicone-Coated Surfaces

Silicone-based adhesives

Mechanical attachment

Surface removal of silicone coating

3.For Consistently Wet Areas

Underwater epoxies

Marine-grade sealants

Mechanical clamping systems

Best Practices for Reliable Adhesion

Surface Preparation Checklist

• Clean with appropriate solvent

• Abrade if necessary

• Apply primer when needed

• Ensure complete dryness

• Check temperature (ideal: 15-35°C)

Application Techniques

• Apply firm, even pressure

• Use roller for double sided butyl tape

• Allow 24-48 hours for full bond development

• Avoid stretching during application

• Maintain constant pressure during cure time

FAQ: Butyl Tape Adhesion Questions

Q: Will butyl tape stick to PVC pipes?

A: Most PVC has sufficient surface energy for butyl waterproof tape, but always clean and test first. Some plasticized PVC may cause issues.

Q: Does butyl tape work on painted surfaces?

A: It works well on most cured paints, but may pull off fresh or poorly adhered paint. Test a small area first.

Q: Can I use butyl tape on concrete?

A: Yes, but ensure the surface is dust-free. Sealed or finished concrete may require priming for best results.

Q: Why won't my butyl tape stick to metal roofing?

A: Most metal roofing has protective coatings that prevent adhesion. Clean thoroughly and consider mechanical fasteners instead.

Q: Does temperature affect what butyl tape will stick to?

A: Absolutely. Cold surfaces reduce tack, while hot surfaces can make the tape too soft. Apply between 15-35°C for best results.

Conclusion: Knowing Limits Prevents Problems

Understanding what butyl tape rubber products won't stick to is just as important as knowing what they will adhere to. While butyl tape is remarkably versatile, its limitations on certain plastics, contaminated surfaces, and wet conditions require careful consideration.

The team at QKD has spent over 15 years helping customers navigate these challenges. Whether you're working with standard butyl tape black or specialized double sided butyl tape, proper surface preparation and realistic expectations ensure successful projects every time.

Remember that testing unfamiliar surfaces and following manufacturer recommendations from experienced suppliers like QKD prevents costly rework and ensures your seals last for years. Sometimes the best adhesive strategy involves recognizing when butyl tape isn't the right solution and choosing an alternative approach.